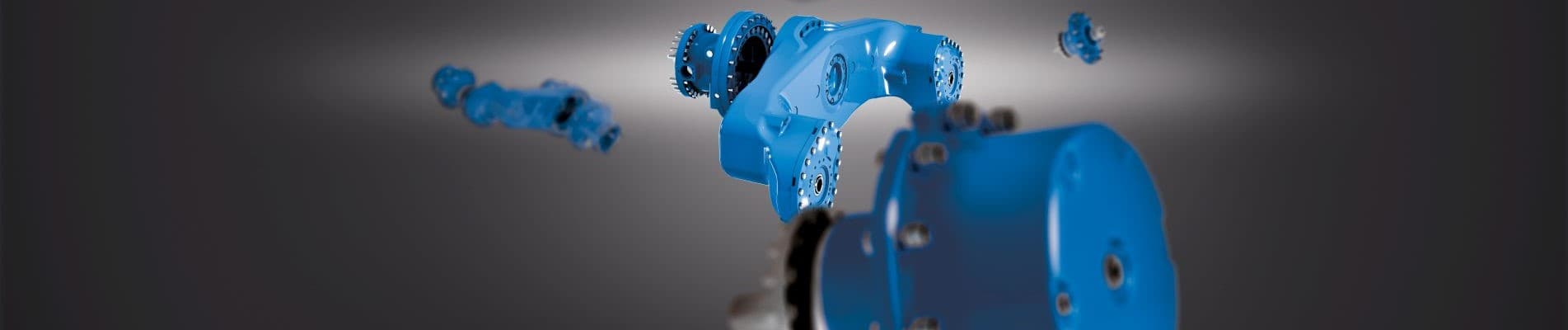

Coherent modular system. Our highly developed set of tried-and-tested components can be configured in almost infinite versions to produce complete drive trains.

YOUR BENEFITS

All modular systems field tested and proven

Rigid and steering axles, tandem axle gearboxes, drives, brakes

Many configuration options

Maximum individuality – modularly developed and implemented. For your specific customer requirement, our well-engineered modular system offers the quick, economical and quality-assured solution.

YOUR BENEFITS

Answer for highly individual challenges

Short development times

Economical, quality-assured delivery

Modular thinking in your customer interest. Our numerous new developments can be integrated directly into the modular system. Each innovation expands the possibilities for the entire product range.

YOUR BENEFITS

5% of annual turnover spent on research and development

Constant new developments

Each innovation fits into the modular system

Fluid customised fabrication based on the modular building-block and procurement principle. You receive individual products without having to give up the benefits of high-volume ranges.

YOUR BENEFITS

One-piece flow on a modular basis

Individual products

Cost benefits, short delivery times, reduced warehousing

Systematic approach to repairs and spare parts for minimised lifetime costs and downtimes. The modular principle, complemented by the constant availability of spare parts and comprehensive customer support, also pays dividends in the long run.

YOUR BENEFITS

More systematic approach to maintenance & repairs

Spare parts available at short notice

Low lifetime costs

Corporate culture based on responsibility and highly skilled production method. Your axles and drives are produced by skilled workers who have been working with the modular system for many years and take personal responsibility for each stage in the process.

YOUR BENEFITS

Individual responsibility of the staff

Not just monotonous mass production

Reliable quality monitoring